PhonlamaiPhoto/iStock via Getty Images

Applied materials (NASDAQ:AMAT) unveiled a new tool on Tuesday that it said will help reduce semiconductor manufacturing costs.

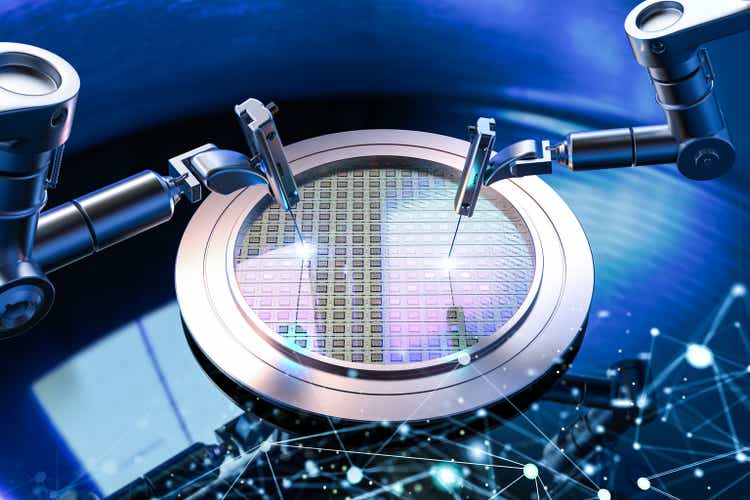

The new technology, known as Sculpta, will help companies reduce the cost of the lithography process, which uses light put patterns on wafers that are used to make semiconductors.

Lithography incorporates light to print patterns on wafers, something that can happen multiple times per wafer.

Applied Materials (AMAT) said it could save customers up to $250 million per 100,000 wafer starts per month of production capacity, along with manufacturing cost savings of approximately $50 per wafer.

There are also environmental benefits, as it could reduce energy and water use, while reducing greenhouse gas emissions by more than 0.35 kilograms of carbon dioxide equivalent per wafer.

“The new Sculpta system is a great example of how advances in materials engineering can complement [extreme ultraviolet] lithography to help chipmakers optimize chip area and cost while addressing the growing economic and environmental challenges of advanced chip manufacturing,” said Applied Materials (AMAT) senior vice president Dr. Prabu Raja, in a statement.

Shares of Applied Materials (AMAT) rose nearly 2% in premarket trading after the announcement.

Santa Clara, California-based Applied Materials (AMAT) said its Sculpta tool will allow customers to use a light for the first pattern and then sculpt the final pattern from that.

Separately Tuesday, Applied Materials (AMAT) introduced a new eBeam metrology system to speed up the chip manufacturing process and help maximize yields.